Kerfcore is a stable substrate that has been kerfed into small rib sections that are joined together with a very flexible latex impregnated paper. This allows for the attachment of high pressure laminates, veneers, metals and other semi-rigid materials laminated flat and then formed into virtually any shape.

Kerfkore Products

Kerfkore Company is your primary source for environmentally friendly bendable substrates and lightweight structural composite panels. We can help you create that radius project quickly and economically, provide environmentally friendly products, and help reduce weight for those special applications. Our products are used to create: architectural panels, shelving, partitions, ceiling panels, columns, wall systems, signage, displays, theatre props, swing doors, elevators, kiosks, movable food carts, table tops, furniture, cabinets, motor homes, boats, and much more.

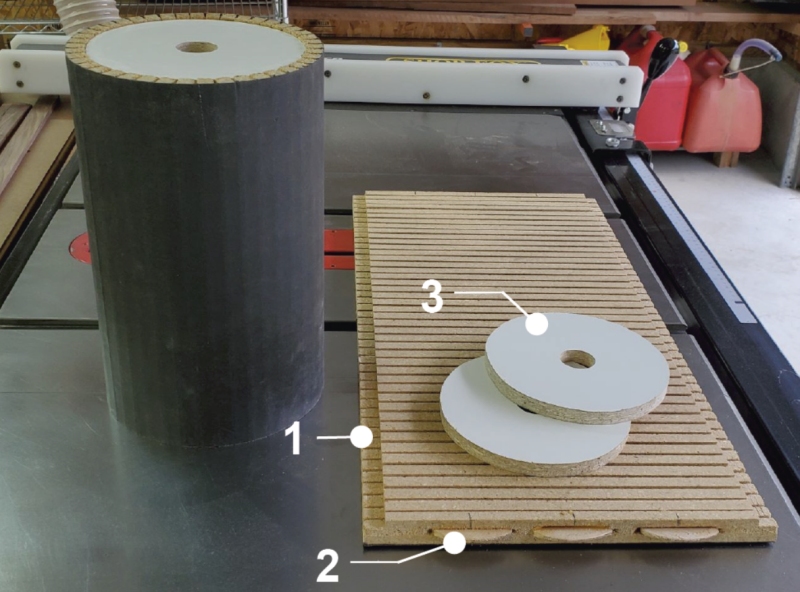

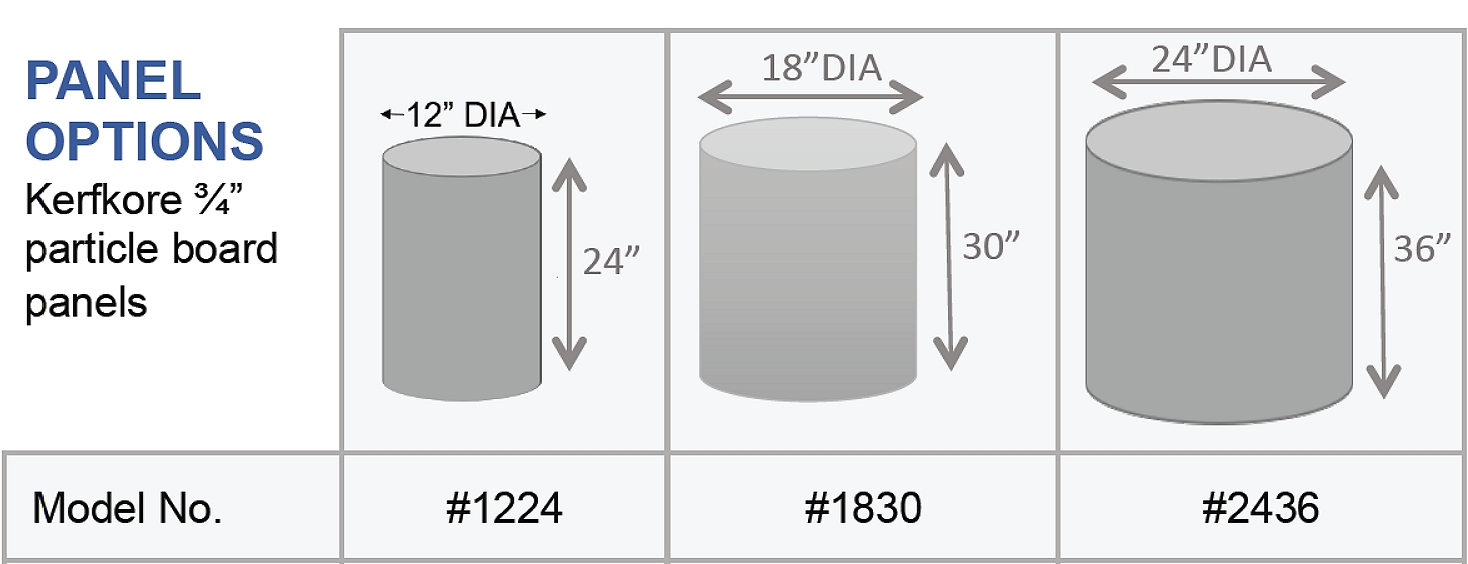

DIY Cylinder Forms with Kerfkore

It’s easy to make your own cylinder forms with Kerfkore ¾” particle board panels.

It’s easy to make your own cylinder forms with Kerfkore ¾” particle board panels.

- Rabbet top and bottom of purchased Kerfkore panel

- Join edges with biscuits to form cylinder

- Add circular top and bottom pieces

Finish with veneer or laminate, etc. (not shown)

Customer provides additional materials and tools (biscuits, veneer or laminate, adhesives, stains and finishes, router and rabbet bits, etc.)

Contact GTMS for comments on our new Kerfkore products.

Kerfkore Architectural and Distributor Sample Kits

Kerfkore architectural and distributor sample kits have been redesigned to provide a more appealing and better demonstration of our products.

Kerfkore architectural and distributor sample kits have been redesigned to provide a more appealing and better demonstration of our products.

Kerfkore Architectural Kits have been redesigned into a branded self-ship box that immediately grabs the customer’s attention and lets them know where it is from when it arrives at their doorstep. The kit includes: Kerfkore, Timberflex, Flexboard, Econokore, Worklite EPS Foamkore, and Worklite XPS Foamkore samples. A product chart is also included to provide a top line comparison of each product.

Kerfkore Sample Chain Sets have been redesigned in a new branded sleeve reducing the amount of packaging while creating an attention-grabbing marketing promotion. When ordering, please be aware that all chain samples will be sent out in quantities of 25. (i.e. 1 unit = 25 chain sets). Forward orders, questions, suggestions, or feedback to roger@georgetownmarketing.com

Product Index

Kerfkore

Kerfkore enables you to laminate first with HPL metal, veneer and other semi rigid materials and then bend into the desired shape down to 3″ in radius.

Visit the Kerfkore Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

Timberflex

Timberflex is a superior quality product with an Italian poplar face ready to be formed first into desired shapes down to 5in radius then laminated traditionally.

Visit the Timberflex Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

Flexboard

Flexboard has a uniform and stable overlay that allows for traditional face application after forming. It is suitable for veneer lamination prior to bending.

Visit the Flexboard Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

EconoKORE

EconoKORE is a low cost alternative for radius projects. Its two ply construction provides a uniform durable product with thickness options of 1/4in and 3/8in.

Visit the EconoKORE Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

Worklite

Worklite will be available with two core options EPS Foamkore and XPS Foamkore. Worklite EPS Foamkore is our current white Styrofoam core and Worklite XPS Foamkore is our current blue Styrofoam core. There are no changes to product sku numbers and for the next year we will include “Formerly Foamkore” on all communications. The new name is effective immediately.

Visit the Worklite Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

Beadboard

Beadboard is a stable MDF panel available plain or with different high quality face veneers suitable for wall treatment and furniture usage.

Visit the Beadboard Page for links to more information including Spec Sheet, Do’s and Don’ts, SDS Sheet, and 3 Part Specs.

Italian Bending Poplar Plywood

Italian Bending Poplar Plywood is a flexible 1/8″ material that can be formed into curves and radii providing a smooth face surface. It is produced under strict tolerances and high standards with superior quality Italian Poplar veneer. The Italian Bending Poplar can be used painted, stained, laminated or left unfinished.